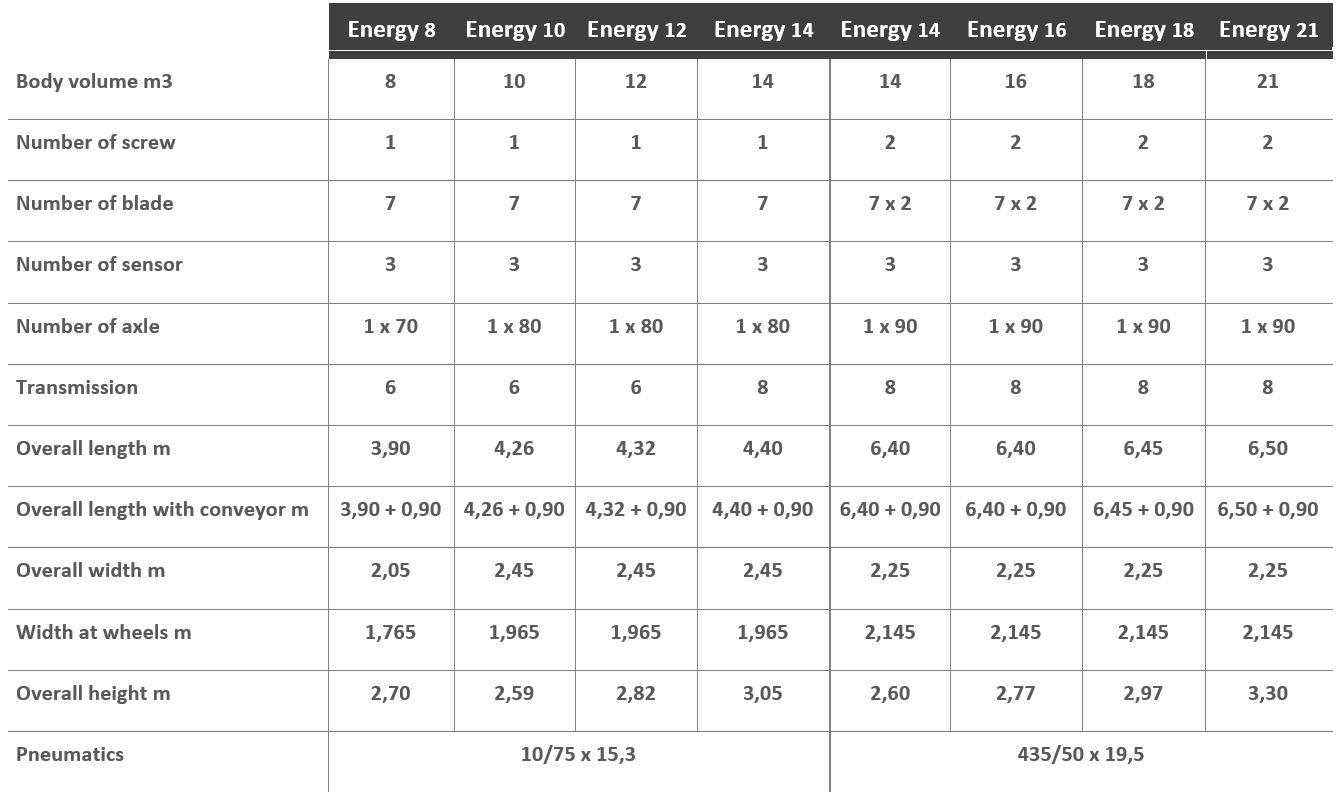

VERTICAL MIXER WITH 1 OR 2 SCREW(S) ENERGY

STANDARD EQUIPMENT

Mixing – Dispensing

Vertical conic mixing screw equipped with 7 blades and with an adjustable scraper

540 rpm gear = 32 turn at the screw (8, 14, 16, 18 et 21 m3)

540 rpm gear = 22 turn at the screw – 1000 rpm gear = 40 turn at the screw (10 , 12 et 14 m 3)

Conic circle with an anti-flood ring inserted in the vat

Fiber hoop

Angle reverser reducer with oil bath (tank capacity 4l)

2 manual vertical contra-rotating blades

Tangential unloading trap door front right hand side or rear left hand side

Front left control ladder (or rear central if front conveyor)

Conception – Safety

Chassis integrated to the vat (narrow and low model)

Weighing DG500, 3 points, 48 programs, 18 components with horn (2 points on the axle, 1 point on the linkage)

Safety casing

Road traffic

Parking brake and hydraulic brake

Lighting in accordance to the Highway code

Manual kickstand

Linkage on piton

Revolving light

CE norms and DREAL homologation

PTO Transmission

PTO transmission serie 8 with protection and safety bowl machine side

Tractor equipment

1 plug 540 rpm and 1000 rpm

1 electric plug 12v/3 pins for weighing

1 electric plug 12v/7 pins for light

1 hydraulic distributor 1 DE for the trap door (be carefull of the quantity if additional equipment)

1 linkage piton

ADDITIONAL EQUIPMENT :

Dispensing

– Pack front bilateral conveyor with chains and bars 0,80 m width (R or L dispensing, gearbox 2 gears, control footbridge) (1 DE) – cancels the side trap and the ladder

– Inclined conveyor 0,80 m width for 0,60 m to 1,10 m feed with hydraulic dish, inclined side 0,30 m (1 DE)

– Hydraulic dish of the conveyor 0,30 m R or L or 0,20 dish R or L (1 DE)

– Stainless steel conveyor 0,80 m width

– Bilateral PVC conveyor flat only 0,80 m width replacing chains and bars

– Banana front conveyor, chains and bars 0,80 m width (R and L dispensing, hydraulic dish 0,20 m height maxi 1 m, gearbox 2 gears, control footbridge) (1 DE) – cancels the side trap and the ladder

– Right lateral PVC conveyor 0,80 m length, 1,10 m width, hydraulic inclination (2 DE)

– Central rear conveyor 2,00 m length, 1,10 m width, hydraulic lifting by 2 cylinders dispensing H. 2,50 m

– Rear bilateral unloading conveyor chains and bars 0,80 m width – cancels the front trap door

– Banana front conveyor, chains and bars 0,80 m width (R and L dispensing, hydraulic dish 0,20 m height maxi 1 m (2DE) – cancels the front trap door

– Footbridge replacing the ladder

– Cone for minerals loading (rear)

– Build-up vat for 1 screw machine (increases the height of 0,30 m +2m3)

– Build-up vat for 2 screws machine (increases the height of 0,30 m +3m3)

Hydraulic – Electric

– Gearbox 2 gears

– Speed shifting by teleflexible screw box

– Hydraulic speed shifting screw box tractor distributor (1 DE)

– Speed shifting electric control (1 add. Function) screw box

– Additional function for electric distributor

– Hydraulic selector 2 or 3 functions electric control for machine without conveyor (1 DE tractor)

– Double electric control near the conveyor (3 functions)

– Electric flow regulator in tractor’s cab for unloading conveyor (1 sens)

– Manual flow regulator for unloading conveyor (1 sens)

– MOTEC camera with screen

– Additional MOTEC camera

Cutting system

– 1 additional manual vertical contra-rotating blade

– 2 hydraulic vertical contra-rotating blade to replace the 2 manual ones (1DE)

– 1 additional manual horizontal contra-rotating blade

– 1 additional hydraulic horizontal contra-rotating blade (1 DE)

– 2 hydraulic contra-rotating blades for tubercules and roots (1 DE)

– Extension of knives for long straw

– 2nd scraper on 1 screw model

Transmission

– Standard PTO transmission serie 8 with protection

– Wide angle PTO transmission serie 8 tractor side with protection

Pneumatics

– 2 wheels 400×15,5 replacing the 10/75 x 15,3 ones

– Spare wheel 435/50 x 19,5

VIDEO

DOWNLOAD PRODUCT SHEET

Télécharger la fiche produit