Vertical mixers | Marque : Jeulin

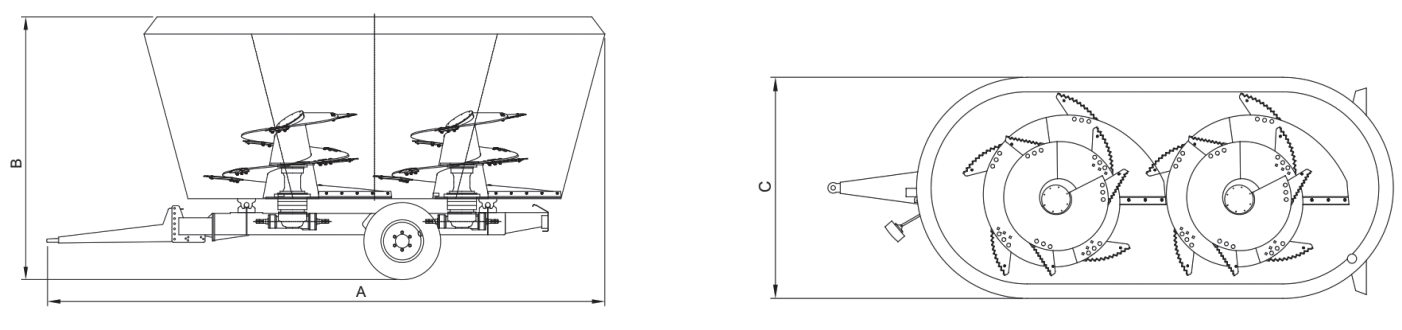

This mixer has an independent chassis which enables more precise weighing. It is able to ensure a homogeneous mixing and optimal dispensing thanks to the mixing screws which, on the 2-screw models, intersect due to the J-FLOW system thus offering a high degree of efficiency.

Download the brochure

Download started

If not, click here.

Are you interested in this model?

| ACTIVA 10 | ACTIVA 12 | ACTIVA 14 | ACTIVA 17 | ACTIVA 16 | ACTIVA 18 | ACTIVA 20 | ACTIVA 22 | ACTIVA 24 | ACTIVA 26 | ACTIVA 28 | ACTIVA 30 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A - Longueur hors tout (m)* | 4.30 | 4.35 | 5.75 | 5.75 | 6.38 | 6.45 | 6.5 | 6.52 | 6.54 | 6.88 | 6.93 | 6.93 |

| B - Hauteur hors tout (m) | 2.7 | 2.95 | 2.95 | 3.3 | 2.67 | 2.77 | 2.87 | 2.97 | 3.07 | 3.30 | 3.45 | 3.55 |

| C - Largeur hors tout (m) | 2.47 | 2.47 | 2.55 | 2.55 | 2.45 | 2.55 | 2.55 | 2.55 | 2.55 | 2.55 | 2.55 | 2.55 |

| Volume de cuve m3 | 10 | 12 | 14 | 17 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 |

| Nombre de vis | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Nombre de couteaux | 8 | 8 | 8 | 8 | 8×2 | 8×2 | 8×2 | 8×2 | 8×2 | 9×2 | 9×2 | 9×2 |

| Nombre de pesons | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 6 | 6 | 6 |

| Nombre d'essieux | 1×80 | 1×80 | 1×90 | 1×90 | 1x 100 | 1x 100 | 1× 100 | 1×100 | 1× 100 | Boggie essieu suiveur 2x 100 | ||

| Transmission serie | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| Largeur aux roues (m) | 2.05 | 2.05 | 2.18 | 2.18 | 2.245 | 2.245 | 2.245 | 2.245 | 2.245 | 2.43 | 2.43 | 2.43 |

| Pneumatiques | 400/60x15.5 (390x840 mm) | 445/50R 19.5 (430 x930 mm) | ||||||||||

| Poids à vide (kg) | 4400 | 4400 | 4690 | 4690 | 7000 | 7000 | 7000 | 7000 | 7000 | 8150 | 8350 | 8550 |

| *si tapis longueur hors tout +1.40 m | ||||||||||||

The wrapping season is fast approaching! To ensure optimal conservation of fodder and meet the needs of breeders and farmers, JEULIN offers the Anderson Group’s range of inline wrappers, recognized for its reliability and unmatched performance. A true complement to the range of individual wrappers already offered, this system has several advantages over individual bale […]

Read more

At the beginning of this year, Jeulin is pleased to announce the release of the brand new version of the Hélicut straw blower, which incorporates notable innovations to offer more performance and flexibility to users.This new generation of the famous straw blower is now equipped with 3 interchangeable grid models as standard, a major development […]

Read more

Jeulin is proud to announce the launch of the new Sirius 180 straw blower, recently presented at the Sommet de l’Élevage in Clermont-Ferrand. This innovative machine, designed for producers wishing to combine performance and efficiency, meets the specific requirements of professional users. The Sirius 180 straw blower, with a capacity of 18m³, is equipped with […]

Read more